Revolutionizing PCB Rework: Digital Microscopes Enhance Accuracy and Reduce Fatigue for Electronics Repair Technicians

The miniaturization of electronics has made Printed Circuit Board (PCB) assembly and rework incredibly demanding. Technicians are required to solder and inspect components smaller than a grain of rice, such as 0201 packages and micro-BGAs. Eye strain, neck fatigue, and human error are significant challenges that can lead to costly board scrapping.

A contract electronics manufacturing service (EMS) in specializing in prototyping and high-mix, low-volume production was experiencing high scrap rates on expensive multi-layer boards. Technicians relied on traditional bench microscopes for rework, which offered a limited field of view, fixed working distance, and no ability to document findings. This led to inspection inconsistencies and repetitive strain injuries, affecting both quality and employee well-being.

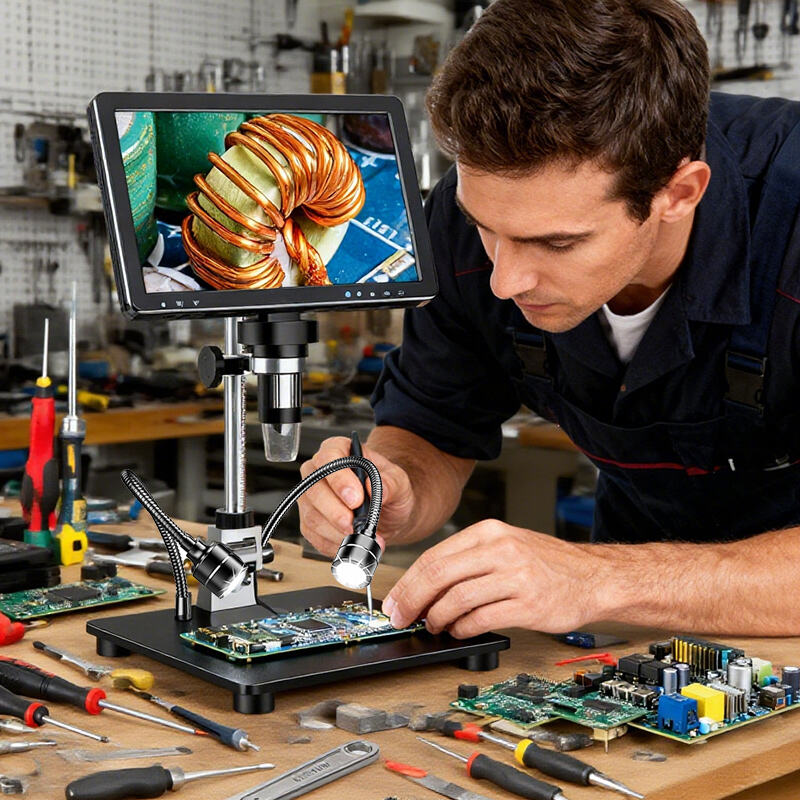

The facility upgraded ten of its rework stations with the ProSeries Trinocular Digital Microscope. This solution offered transformative benefits:

Ergonomic HD Display: The microscope feeds a real-time, high-definition image to a large 24-inch monitor. Technicians can now work in a comfortable, upright posture, eliminating neck and eye strain and dramatically improving focus during extended shifts.

Enhanced Depth of Field and Zoom: The large zoom range and superior depth of field provided a crisp, clear view of solder joints under components like BGAs, making it easy to identify bridging, cold joints, or tombstoning without constant refocusing.

Documentation and Collaboration: The trinocular port allowed for the connection of a high-resolution camera to capture images and video of defects for quality reports, client communication, and technician training. This created a valuable knowledge base and ensured consistency across shifts.

The scrap rate on reworked boards plummeted by over 65% within three months. Technician productivity increased as they could work faster and with greater accuracy. Furthermore, reports of work-related discomfort ceased entirely. The ability to capture and share images improved training for new hires and provided clear evidence for client reviews, enhancing the company's reputation for meticulous quality. The digital microscopes became a critical tool for maintaining a competitive edge in high-precision electronics manufacturing.