When working with intricate electronic components and circuit boards, precision becomes paramount for successful repairs and assembly work. Modern electronics have evolved to feature increasingly smaller components, making traditional magnifying glasses insufficient for detailed inspection and manipulation. A high-quality microscope for soldering transforms your workspace into a professional-grade environment where every connection, trace, and component becomes clearly visible, enabling precise work that would otherwise be impossible with the naked eye.

Professional technicians and hobbyists alike have discovered that investing in proper magnification equipment significantly improves work quality while reducing eye strain during extended sessions. The ability to see fine details clearly not only enhances accuracy but also prevents costly mistakes that can damage sensitive electronic components. Understanding the various types and features available will help you make an informed decision that matches your specific needs and budget requirements.

Understanding Different Types of Soldering Microscopes

Stereo Microscopes for Three-Dimensional Work

Stereo microscopes provide depth perception through dual optical paths, creating a three-dimensional view that proves invaluable when working with layered circuit boards and complex assemblies. This type of microscope for soldering offers magnification ranges typically between 10x to 40x, which provides the perfect balance between detail visibility and working distance. The stereo design allows operators to maintain natural hand-eye coordination while performing delicate soldering tasks, making it easier to judge distances and component relationships accurately.

The working distance of stereo microscopes typically ranges from 4 to 6 inches, providing ample space for soldering iron maneuvering and component placement. Many models feature adjustable magnification through zoom mechanisms, allowing users to switch between overview and detail modes without changing eyepieces or repositioning the workpiece. This flexibility proves essential when transitioning between different phases of repair work or when examining various component sizes within the same project.

Digital Microscopes with LCD Displays

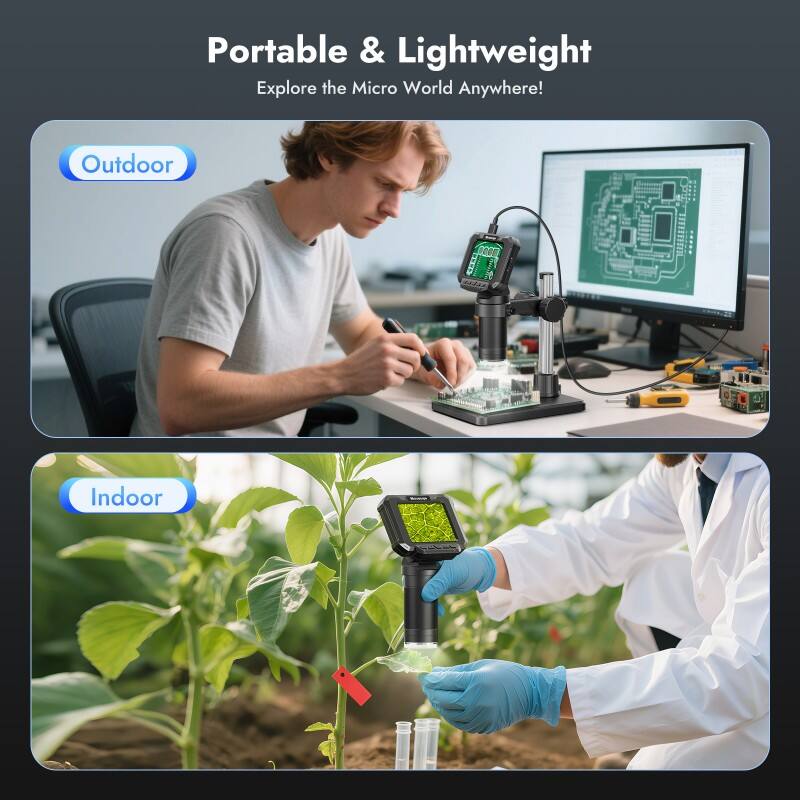

Digital microscopes represent the modern evolution of magnification technology, featuring built-in cameras and LCD screens that eliminate the need for eyepieces entirely. These systems capture high-resolution images of the work area and display them on screens ranging from 4 to 10 inches, providing comfortable viewing angles that reduce neck strain during extended work sessions. The digital format also enables easy documentation of work progress and sharing of findings with colleagues or clients.

Advanced digital models offer features such as image capture, video recording, and measurement tools that enhance productivity and quality control processes. The ability to freeze images for detailed analysis or comparison proves particularly valuable when troubleshooting complex issues or when teaching soldering techniques to others. Some digital microscopes also include wireless connectivity options, allowing remote viewing and collaboration capabilities that expand their utility beyond traditional workshop applications.

Essential Features for Optimal Soldering Performance

Magnification Range and Optical Quality

The magnification capabilities of your chosen microscope directly impact the level of detail you can achieve in your soldering work. Most professional applications require magnification levels between 20x and 60x, though some specialized tasks may benefit from higher ranges up to 100x or more. However, higher magnification often comes with trade-offs in working distance and field of view, requiring careful consideration of your typical work requirements and component sizes.

Optical quality determines the clarity, color accuracy, and contrast of the magnified image, directly affecting your ability to distinguish between different materials and identify potential issues. High-quality lenses minimize chromatic aberration and distortion while maximizing light transmission for bright, clear images. When evaluating optical systems, consider factors such as lens coatings, glass quality, and the overall design philosophy of the manufacturer, as these elements significantly impact long-term performance and user satisfaction.

Illumination Systems and Light Quality

Proper illumination forms the foundation of effective microscopy work, with inadequate lighting leading to eye strain, reduced accuracy, and missed details during critical operations. LED lighting systems have become the standard for modern soldering microscopes due to their long lifespan, low heat generation, and excellent color rendering properties. The positioning and intensity control of illumination sources should allow for even coverage of the work area without creating harsh shadows or reflective glare.

Adjustable lighting intensity proves essential when working with different materials and surface finishes, as reflective components may require reduced illumination while dark substrates benefit from increased brightness. Some advanced systems incorporate multiple lighting angles or ring illumination to eliminate shadows completely and provide uniform coverage across the entire field of view. The color temperature of the lighting should closely match daylight specifications to ensure accurate color perception during component identification and quality assessment tasks.

Working Distance and Ergonomic Considerations

Optimal Working Distance for Tool Access

Working distance refers to the space between the objective lens and the workpiece, directly affecting your ability to maneuver soldering tools and position components effectively. A microscope for soldering should provide sufficient clearance for comfortable tool manipulation while maintaining sharp focus and adequate magnification levels. Most professional applications require working distances of at least 4 inches to accommodate standard soldering iron sizes and allow for natural hand positioning during extended work sessions.

Longer working distances also provide benefits in terms of safety and cleanliness, keeping the optical components away from soldering fumes and potential flux splatter that could damage delicate lens surfaces. However, increased working distance often requires larger objective lenses and more complex optical designs to maintain image quality, potentially increasing the overall cost and size of the microscope system. Finding the right balance between accessibility and optical performance requires careful consideration of your specific application requirements and workspace constraints.

Adjustability and User Comfort Features

Extended soldering sessions demand comfortable viewing positions to prevent fatigue and maintain consistent work quality throughout the day. Adjustable eyepiece angles, interpupillary distance settings, and diopter corrections ensure that users can achieve optimal viewing comfort regardless of their physical characteristics or vision requirements. These adjustments become particularly important in professional environments where multiple operators may share the same equipment.

Height adjustability and tilting mechanisms allow users to position the microscope at ergonomically correct angles that minimize neck and back strain during prolonged use. Some advanced systems incorporate motorized adjustments or memory settings that enable quick transitions between different operators or work configurations. The stability of adjustment mechanisms should maintain their settings reliably over time, preventing drift or loosening that could affect image quality or user comfort during critical operations.

Specialized Applications and Industry Requirements

Electronics Repair and PCB Inspection

Modern printed circuit boards feature component densities that challenge traditional repair methods, with surface-mount devices measuring less than 0.5mm in some applications. Professional electronics repair requires microscope systems capable of resolving fine pitch connections, identifying lifted pads, and detecting microscopic fractures in solder joints that could cause intermittent failures. The ability to examine both the component and substrate simultaneously proves crucial for accurate diagnosis and successful repair outcomes.

Multi-layer PCBs present additional challenges due to their complex internal structures and varying surface textures that can affect optical performance. Specialized microscope configurations may include oblique lighting options or polarization filters that enhance contrast and reveal details that would otherwise remain hidden under standard illumination conditions. Documentation capabilities become particularly valuable in this application area, allowing technicians to record evidence of damage or demonstrate repair quality to customers and quality control departments.

Research and Development Applications

Research and development environments often require more advanced microscope features to support prototype development, failure analysis, and quality assurance activities. Higher magnification ranges, specialized lighting techniques, and measurement capabilities enable detailed characterization of new materials, joint formation processes, and long-term reliability studies. These applications may also benefit from image analysis software that can automatically detect and quantify various features or defects.

Collaborative research efforts increasingly rely on digital documentation and remote consultation capabilities that modern microscope systems can provide through network connectivity and cloud-based sharing platforms. The ability to capture high-resolution images and videos with embedded measurement data supports comprehensive reporting and enables effective communication of findings across interdisciplinary teams. Advanced systems may also integrate with laboratory information management systems to automate data collection and ensure traceability of test results.

Budget Considerations and Value Assessment

Entry-Level Options for Hobbyists

Hobbyist-level microscopes typically offer basic magnification and illumination features at accessible price points, making professional-quality soldering assistance available to home workshops and small-scale operations. These systems often sacrifice some advanced features in favor of affordability while still providing significant improvements over traditional magnifying glasses or basic inspection tools. Understanding the limitations and capabilities of entry-level options helps ensure realistic expectations and successful implementation.

Digital microscopes in the entry-level category frequently offer excellent value propositions by combining modern display technology with simplified optical systems that reduce manufacturing costs while maintaining usable image quality. Many of these systems include basic measurement tools and image capture capabilities that were previously available only in professional-grade equipment. The key to success with budget options lies in matching their capabilities to your specific needs rather than expecting universal performance across all possible applications.

Professional-Grade Investment Considerations

Professional microscope systems represent significant capital investments that should be evaluated based on long-term productivity gains, quality improvements, and operational cost reductions rather than initial purchase price alone. Higher-end systems typically offer superior optical performance, greater durability, and more extensive feature sets that justify their premium pricing through enhanced capabilities and extended service life. The total cost of ownership should include considerations for maintenance, calibration, and potential upgrade requirements over the expected operational lifetime.

Return on investment calculations for professional systems should account for factors such as reduced rework rates, improved first-pass yields, decreased eye strain and associated productivity losses, and enhanced capability to handle more complex or profitable work. Many professional systems also retain better resale values and offer upgrade paths that protect the initial investment while allowing for capability expansion as business needs evolve. Service and support availability from established manufacturers provides additional value through minimized downtime and access to expert technical assistance.

FAQ

What magnification level is best for most soldering applications

Most general soldering work benefits from magnification levels between 20x and 40x, which provide sufficient detail visibility while maintaining adequate working distance for tool manipulation. Surface-mount device work may require higher magnifications up to 60x or 80x, while through-hole component assembly typically works well at lower magnifications around 10x to 20x. The key is selecting a system with adjustable magnification to handle various component sizes and detail requirements within your typical workflow.

How important is the working distance when choosing a soldering microscope

Working distance critically affects your ability to maneuver soldering tools and access components effectively during repair operations. A minimum working distance of 4 inches is recommended for most applications, with 6 inches or more preferred for complex assemblies or when using larger soldering equipment. Insufficient working distance restricts tool access and can lead to accidental contact with the microscope objective, potentially causing damage to both the optical system and your workpiece.

Are digital microscopes better than traditional optical microscopes for soldering

Digital microscopes offer advantages in terms of viewing comfort, documentation capabilities, and collaboration features, while traditional optical systems typically provide superior image quality and more natural depth perception. Digital systems eliminate neck strain by displaying images on screens at comfortable viewing angles and enable easy sharing of findings with others. However, optical systems often deliver better resolution, color accuracy, and three-dimensional visualization that some users prefer for precise manipulation tasks.

What maintenance requirements should I expect with a soldering microscope

Regular maintenance includes cleaning optical surfaces with appropriate solutions and lint-free materials, checking and adjusting illumination systems, and protecting the equipment from soldering fumes and flux contamination. LED lighting systems typically require minimal maintenance compared to traditional bulbs, while mechanical adjustments may need periodic lubrication or calibration depending on usage intensity. Proper storage in clean, dry conditions and regular inspection of moving parts will maximize the operational lifetime and maintain optimal performance of your investment.